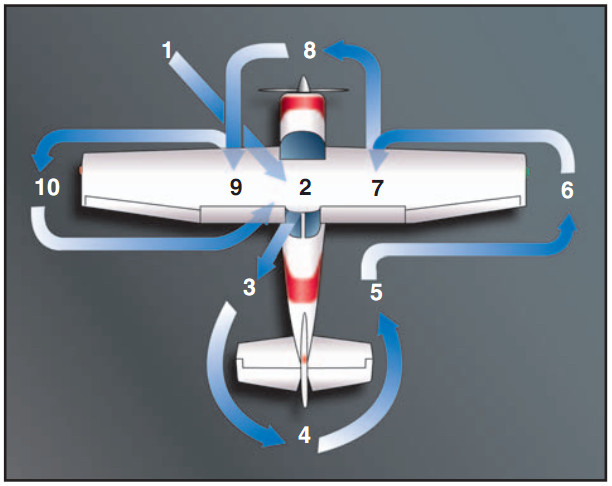

Pilots usually don’t fly before they make sure the plane will. Or rather, that it will probably continue flying once it’s up in the air. They’ll do a thorough walk-around and pre-flight before slamming the throttles home and rotating.

The stakes aren’t as high with things that don’t fly, of course – but it’s still sound policy to do a “pre-flight” check of any car that isn’t a relatively new car – and especially if it’s a vintage car that only gets taken out every once in awhile.

Because in-between, things can run low.

Air, for instance.

Most cars made before the late ‘90s do not have tire pressure monitors – which you really shouldn’t trust without verifying, either – so it’s up to you to monitor the tire pressure. The older the tires the more likely they – or the valve stems – are leaking, even if it’s only a little.

Over time, it can amount to a lot.

And it may not look it.

Tires can be low but not obviously so.

But being down 15 pounds on the right rear can dramatically change the way your car handles – and brakes – and not for the better. It also increases the likelihood of a tire failing due to friction and heat build-up.

Besides checking tire pressure – manually, with an accurate gauge – it’s a good idea to check the tires themselves for signs of dry rot, such as cracks on the sidewall or bulges on the sidewall; the sight of either indicates a tire that is need of being replaced before you drive the car.

This happens fairly often with little used vintage cars – which often have vintage tires.

My ’76 Trans-Am, for example, is wearing a set of BF Goodrich radials that date from the late ‘90s – because I only drive the TA once or twice a month. Even though the tread is still good, the rubber almost certainly isn’t what it was. If I were going to drive the TA every day – or aggressively, at high speed – I would replace these tires even though they look good.

Oil and other vital fluids can also run low – whether by leaks or via consumption. All engines use some oil but ancient engines often use more – not necessarily because they’re worn but because they were designed with looser tolerance than modern engines.

Especially vintage high-performance engines.

I always confirm the oil level is right before I turn the key. A moment spent checking the dipstick – and checking for puddles underneath the car – could be the difference between adding a couple of quarts and something a lot more expensive than that. Large puddles – or new ones – are cause for finding out why and where it’s coming from before you go anywhere.

In that car, at any rate.

If the car has an automatic transmission, confirm it’s full, too. You can kill an automatic in just a few minutes of driving if it’s down on fluid by more than a couple of quarts – and in any case, you need to figure out why it’s low before you try to drive it.

Old cars spring leaks – just like old people. Gaskets shrink and crack; hoses deteriorate. Clamps no longer do.

It might be minor – but it could become something major.

Now is also the time to make sure the radiator isn’t leaking and that the brake master cylinder is full. Anyone who has ever owned a vintage car knows about their inclination to overheat – even when everything is in order. If the radiator is down a half-gallon, that inclination will increase.

And checking the radiator every so often will also keep your eye on the coolant’s color. Most vintage cars used green ethylene glycol (many modern cars have orange or other colored coolant) and that’s how it ought to look. If it’s brown, you probably need to change it – even if the level’s right. It’s good policy to do that every three years or so – no matter how few miles the car is driven. Chemical reactions occur inside the cooling system that break down the coolant, which can lead to sludge inside your radiator and the engine.

Now is also a good time to visually inspect all hoses for signs of leaks – and bulges or softness. The rubber should feel firm but pliable. Like tires, rubber hoses age even if the car isn’t used much. Don’t go by mileage; go by condition.

Old car braking systems are more prone to leaks because they’re old.

Especially if you haven’t kept up with regular (a good rule of thumb is every five years, at least) brake fluid changes. Moisture inevitably gets into the system and then you get rust inside the lines; rubber parts in wheel cylinders and calipers break down – and when they do, you may find it hard to stop.

Look at drive belts, too. Cracks indicate a break is in your future. Much less hassle to deal with this in your garage than out on the road.

The final thing I do is also the same thing pilots do: I let the engine warm up and monitor the gauges; if everything looks right – and sounds right – it’s ok to point her into the wind and put the balls to the wall!

…

Got a question about cars – or anything else? Click on the “ask Eric” link and send ’em in!

If you like what you’ve found here please consider supporting EPautos.

We depend on you to keep the wheels turning!

Our donate button is here.

If you prefer not to use PayPal, our mailing address is:

EPautos

721 Hummingbird Lane SE

Copper Hill, VA 24079

PS: Get an EPautos magnet (pictured below) in return for a $20 or more one-time donation or a $10 or more monthly recurring donation. (Please be sure to tell us you want a sticker – and also, provide an address, so we know where to mail the thing!)

My latest eBook is also available for your favorite price – free! Click here.

Eric – the old “Rule of thumb” was ONCE A MONTH or every fill of the tank to check the engine oil, and the TIRES’ respective PRESSURE. My Dad, being a 20 yr. man in the USAF, retiring a major, after navigating a B-52 (and was deputy squadron commander), having killed many “Monkeys and Snakes” there in ‘Nam, did teach me likewise to “pre-flight” my ride and to be diligent with the maintenance. He told me of a tale how a “BUFF” was nearly lost (this was prior to the first one being shot down in Sept of ’72) due to the negligence and outright falsification of maintenance records; the E-5 involved got an “Article 15” and lost a stripe, the crew chief, an E-7, was court-martialed, busted to Airman Basic, did 90 days in confinement, and lost his pension. The USAF doesn’t screw around!

EP you come across rather differently on video than you do in text only. Don’t leave home without sail-fawn and cute little jump starter? I felt like I was watching car & driver for girl scouts. C’mon what self congratulatory car expert guy hits the road not knowing the state of his electrical system? And if your your alt burns out far from an auto-zone, no bat booster is gonna get you there. Enjoy all your informative articles, especially the libertarian bent, even paid dues to your site. Anyway, keep up the good work even if the rough & ready road warrior image is smudged.

steve, you must mean you felt like you were reading car and driver in the late 80’s when I gave it up. It was clover city and the staff must have all been neutered.

I certainly don’t feel that way here. They got to where they not only didn’t cuss uncle, they didn’t cuss…nor drink….nor smoke pot…..nor have professional drivers do both and record their times and watch them get faster every drink.

That’s the very reason I like to stop and get a bite to eat and drink a couple beers before going into some hellhole like the Ft. Worth-Dallas metroplex where nearly every driver is insane and the closer you get to rush hour the worse. Heading into Dallas 6 pm in the winter is like playing Russian roulette. Dark makes them even crazier.

Car and Driver was a worthless rag. It suffered too much from “Paris Envy” and related little to “Joe Six-Pack”. Contrary to what those pretentious faggots thought, not EVERYONE aspired to own and drive a “Por-Sha!”.

Oh BTW, “kicking the tires” is not just an old expression.

You can tell if the air pressure is seriously low. Might be hard to do in sandals, though – LOL

We who have driven big rigs always carry some sort of “thumper” on the reach, or perhaps just inside the driver’s door behing the throne. Piece of pipe, a 20 ounce ball pien hammer….. stop to take a leak, then take a tump.. every tyre on the rig gets the same thump. When they are right, they all make a certain sound. If one of them is “off”, it is evident straightaway. Time to take actioin BEFORE the suspect tyre decides to exit the category”tyre” out on the road. I also always carried a hose I made up… on one end the standard “glad hand” air connector, then a long enough shot of hose to reach every tyre on the rig, then a fittint, then the two-headed inflator with a gauge. Blow the trailer park brake, drop the supply air gladhand, connect that to my own hose, , recharge the ‘trailer brakes” with the TPV,charging my hose, then inflate any tures needing a bit of a boost. Stop again after about an hour and recheck the tyre that needed air last stop…. if there is a leak, I could make it quite a ways refilling the tyre at intervals, save the tyre, make my load, then get it fixed on standing time or once I’ve dropped. No tractor with air these days, but I still have that hose….

I use 24″ of 3/4″ rebar. Thumps just right and reaches in on those trailers like drop decks. Also good for self protection.

I just use quick connects on the tractor and trailer air tanks. A short piece of air hose and you can reach everything fine with a clamping chuck….or whatever type of chuck you need. I carry 3 for various types of wheels. When it’s cold as hell you just clamp one on and stand back for a few minutes. No frozen hands from holding that chuck. I carry starting fluid and a lighter for when some a-hole has driven the truck before me and run a tire off the rim. Spray, light, air up and go. You have to wonder what dickheads they are when it takes all day to lose 20 lbs. on that tire. Oh, never mind, I know them by name.

I had a piece of about 1 1/2″ pipe about two feet long that I used as a cheater to clamp down chain binders. I kept it right under the driver’s seat // wink

Truck duals were easy to thump because no rear fenders or bed, just the swivel bunk for the front end of the logs. The trailer just had singles – those army tires – so you had to thump them too when starting off empty. I had a leak (in the tire, that is) when unloading at a remote mill site. By the time I got the logs all rolled off, the tire was plumb out of air pressure but not showing flat at all with the minimal weight of the empty trailer (single axle, NOT tandem). So to heck with it, we just drove home and I drove down to the local store to fix it the next day (they had a compressor that I could borrow back before I jury rigged one of my own). My friend that ran the store couldn’t figure out why I said I needed to fix a flat on the trailer when it was not obviously “flat” – LOL

I finally rigged up a tankless compressor from a reefer unit so I could fix/change tires at home (later the aforementioned mill site, but it had electric) mostly because I got tired of the audience of tourists when I was beating those old split rims in the parking lot.

I bought a 2013 CTS in 2016 with 10.500 miles on it. I was also looking at a freshly restored vintage Chevy pickup with a 350 crate motor and Vintage Air (I’m in AZ so that was essential). Thought long and hard about all the insane electronics on the CTS but also worried about the 350 engine and other old school issues (vapor lock, carb calibration,etc) in 114 degree heat. Still not sure which would have been the bigger problem child as miles add up and things age.

D

Excellent article as always, Eric. Wish I’d read it last year before taking my red Formula out and having the right rear tire come off the rim, sending me into a tree. Too few of these f Body’s are left, gotta do the “pre flight check” you recommend from nice on.

Make sure all the lights work….do not give AGW’s the excuse to create a mobile checkpoint on you over a ‘violation’ that they do not intend to ticket you for but rather use as said excuse.

Last item to check is test the stereo. If functioning, throw in some Van Halen, Deep Purple or Dio and CRANK it Up!!!

I never had any trouble with any of my old Chevys overheating unless they were way low on coolant or something else went wrong, like a bad head gasket.

Back in the early 1970s some dingbat thought it was a good idea to install an aftermarket transmission oil cooler on a cross-flow radiator with those little plastic pins through the radiator core. It took almost 20 years to wear through a pinhole but it wasn’t GM’s fault.

Older cars & trucks have problems primarily due to lack of attention, and old age of everything. Brakes systems rot and corrode when any car or truck sits. Old cars get a bad rap because they generally have sat unmaintained for longer, and once put back into use, hidden defects will usually appear without warning.

Trust me though, newer cars can and do have the same issues. Newer systems can, in most cases, be easier to service, especially front disc brakes vs. front drum brakes. Balancing front brake shoe pressure can be an art with many older vehicles as well, and was mostly abandoned by all manufacturers by 1975.

Rear crankshaft seals are a longer lasting one-piece design, and rack-and-pinion steering can be easier to service in some cases, and not so simple in others. There is still no “maintenance free” car yet, that i’m aware of, and every model out there generally has its own good and bad service issues. There are many chassis platforms that have not aged well, and they are very frustrating to work with, but then a good many of those were a pin to work on when they were new as well. I’ve often seen 2 of the very same car/truck within days of one another, and 1 will have no reliability issues of any kind, and the other will be falling to pieces in every department, lol! This, folks, is just the nature of the beast.

I’ve noticed that the vehicles that reach that magic “million mile” mark are DAILY drivers…which is ipso facto, else how would they reach 1M miles? However, it seems that cars, if properly maintained, don’t necessarily WEAR OUT, but they can AGE or ROT away!

I’d say also the biggest factor to keeping one’s ride fresh and in like-new condition is to GARAGE it when not in use. That’s been a pet peeve of mine, garages are for VEHiCLES. They’re not a place to store excess crap that you should have pitched or garage-saled off, and, most important, keep the garage as YOUR domain, i.e., let the “little woman” arrange the furniture and decorate the rest of the castle as she sees fit, but NOT the garage and/or shop! And understand this…she will be JEALOUS of whatever “man cave” you have, even if it’s just a corner of the garage!

I hate to say it but old cars are generally pretty bad. In my experience the brakes suck, the steering sucks and the reliability is far below a recent vintage car. if you want to get stuck on the side of an interstate an old car is the way to do it. I have two fox body mustangs and just had to put out an engine fire in a hotel parking lot and the other one seems a bit shaky with all the drawbacks i mentioned. Restomods are a better deal in my opinion if you want that old look – which I love – with modern mechanicals.

Eric, a tip to your readers: Every time I change the oil, I draw some brake fluid from the master cylinder. I have a large syringe whose purpose is for precisely measuring 2-cycle oil in gas mixing, so look for one in the lawnmower, or gas can, aisles of the store. I draw down as much as I can, never going below the “min” level marked on the master cylinder. That way, I ensure of never introducing air into the system. The syringe doesn’t draw much: about 150cc’s or so, but in doing it many times a year, the brake fluid is kept fresh w/o having to do a complete drain/bleed job.

that works to an extent and is good for cars with hydraulic clutch cylinders in the bell housing.

A friend was at a garage sale one morning and noticed a used breast pump. It was the same box and manufacturer that made the brake fluid pumps. It was in fact, the very same pump with different attachments. He paid a few bucks for it and had a pump that cost well over $100. I don’t know what attachments he used….on a brake job. I think there was one that sealed well over the bleeder screw.

Go figure.