Being able to fix rather than replace things is probably going to become of greater interest in the years – perhaps weeks – ahead.

One such fixable rather than tossable thing is the now-venerable carburetor, a fuel-delivery device as unknown to most people under 30 today as being able to get on an airplane without being felt up – or a cup of coffee without having to play Sickness Kabuki.

Carburetors mix and distribute fuel mechanically rather than electronically and this accounts for their being fixable rather than tossable.

Repeatedly fixable, in fact.

The device consists of two or three main castings, usually made of aluminum or some other light alloy. These are held together with screws, gaskets sandwiched in between, to keep them from leaking. Inside are a few small parts that regulate the flow of fuel in – and out – of the carburetor, such as the needle and seat and float, as well as some small springs and rubber things that fatigue or otherwise wear out over time.

These small parts do need to be replaced every so often but the carburetor itself soldiers on . . . for decades.

I just finished rebuilding one that dates back to 1978 – decades before Security Theater and the advent of Sickness Kabuki. It is probable it’ll still be mixing air and fuel decades hence, long after both Security Theater and Sickness Kabuki have hopefully become unpleasant memories, fast receding, like images of National Socialist Germany and the Soviet Union.

It’s not a pretty thing to look at unless you understand its beauty.

The carburetor, I mean.

It is a self-contained, completely mechanical device that constitutes the entirety of the “fuel system.” It does literally everything except pump the fuel to itself, which is handled – in cars with carbs – via a simple mechanical pump that is powered by the running engine rather than electricity and which is both cheap – usually less than $50 – and easily accessible, being bolted to the side of the engine, where you can get your hands on it.

The carburetor has no wires because it is not connected to anything electronic. It “senses” only two things: The pressure of your right foot, via a cable attached to the accelerator pedal – and the pull of the engine’s vacuum, which serves to suck the air and fuel mix into the engine.

Physical things, in other words.

It is generally eld to the engine by four bolts. Remove these, disconnect the fuel line and the cable connecting the throttle arm to the accelerator pedal and the carb comes off the engine. It is a ten minute job at the most, if you work slowly. It is also a job anyone with a few very basic hand tools can perform just as well as a trained mechanic because it doesn’t require being a trained mechanic to perform it.

Bring the carburetor over to your work bench. Behold! You are looking at everything – the works. If you fix this, there is nothing else to fix.

Taking it apart and putting it back together again – the rebuilding – does take a little more skill and a few specialized tools. But it doesn’t require hugely expensive diagnostic equipment or the specialized training of a professional “technician.” Chiefly because everything that needs attention can be seen and handled – being mechanical and physical – rather than electronic and invisible.

The thing can be carefully disassembled on the bench, inspected and cleaned. If you are capable of taking measurements and have the simple tools needed, you can handle taking all the measurements necessary to rebuild a carburetor. The cleaning is something anyone who has an old toothbrush and solvent can do.

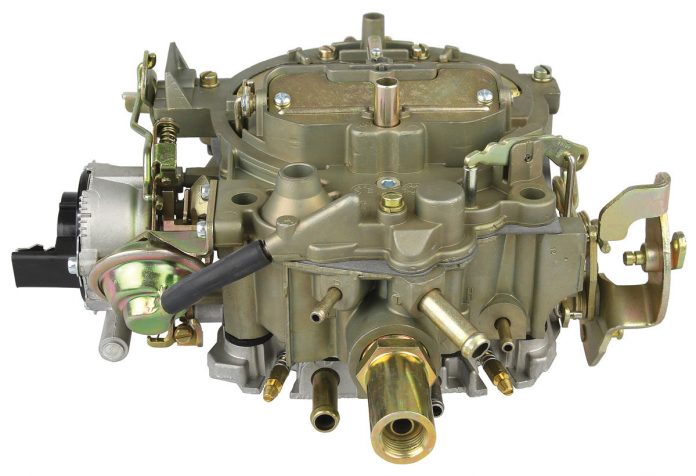

Rebuild kits are available for most popular carburetors, such as this Quadrajet four barrel. The kit will generally contain the small parts that need to be replaced once every 20 years or so. These include the needle and seat, which – along with the float – regulate the entry of fuel into the carb and how much fuel flows through it. Another little item is the accelerator pump, which is what spritzes the gas into the engine when you first push down on the accelerator pedal (after that, negative air pressure – vacuum – sucks the fuel into the engine).

That plus gaskets and careful re-assembly and a few adjustments constitutes the entirety of the rebuilding process and once done the entirety of the fuel delivery system is as functionally new as the day it was first installed on the engine, all those decades ago.

This 1978 Quadrajet is ready for another 42 years of fuel mixing. The Quadrajet mounted on my ’76 Trans-Am has been mixing fuel for 44 years and – absent some intervening political ugliness – it will be mixing it for more decades to come than I probably have left.

Electronic fuel injection has many merits – but rebuildability is not among them. When electronic components stop working, they don’t ever work again. You throw them away and replace them – with new parts. But these new parts – and there are many parts in an EFI system – may not be available in the years – or weeks – to come.

How about the decades to come?

And you may not have the funds to replace all those sensors – and the computer that runs it all. Which you can’t rebuild for $75 on your bench after a little scrubbing with a toothbrush and some solvent.

. . .

Got a question about cars, Libertarian politics – or anything else? Click on the “ask Eric” link and send ’em in!

If you like what you’ve found here please consider supporting EPautos.

We depend on you to keep the wheels turning!

Our donate button is here.

If you prefer not to use PayPal, our mailing address is:

EPautos

721 Hummingbird Lane SE

Copper Hill, VA 24079

PS: Get an EPautos magnet or sticker or coaster in return for a $20 or more one-time donation or a $10 or more monthly recurring donation. (Please be sure to tell us you want a magnet or sticker or coaster – and also, provide an address, so we know where to mail the thing!)

If you’d like an ear tag – custom made! – just ask and it will be delivered.

My latest eBook is also available for your favorite price – free! Click here. If that fails, email me at EPeters952@yahoo.com and I will send you a copy directly!

A few weeks ago the engine was running, not quite right.

So, off with the top!

Then accessing the innards it was found that one of the emulsion tube mixing holes was plugged. Solid.

Guitar wire poker addressed that; back together RUNS GREAT!

Oh, it’s a 1948 Ford 8n, carb has been refreshed at least a couple of times I believe.

Hi Iggy,

To sick freaks like us, this sort of thing is . . . fun!

Of course a RPi wouldn’t be the first choice for truly time critical things for many reasons. But injector hysteresis is going to make any response time pretty slow compared to timing uncertainty and even at high engine RPM a fuel injector pulse is only on the order of a few milliseconds with a cycle time in the several tens of ms.

A RPi can achieve latency of 100 μs per core even allowing Linux to schedule tasks and performance can be improved running ChibiOS or FreeRTOS and Preempt-RT patched kernel to solve some of these shortcomings.

So it’s kind of a question of design need and how much complexity you build in. An F1 car a Corolla is not. Real world EFI control isn’t really *that* critical and even fairly high performance EFI like a MegaSquirt only needed a single core 16-bit 50 MHz processor (ignoring the OS overhead of a RPi it’s still a question of fairly modest requirements for switching time and pulse width given a clock cycle).

Hi Anon,

I like TBI – if I have to have EFI. Almost as simple as a carb. No fuel rail, no multiple injectors, a simple ECU without the need for a hydra of sensors and harnesses. Most even use a carb-type intake manifold. These systems last for 20-plus years in my experience before something needs more attention than cleaning. I don’t know, offhand, whether the TBI unit itself is rebuildable, though. And then there is the question of the electronics – which when they fail, have to be replaced. What if replacement parts aren’t available anymore? In theory the same can be asked about carbs, of course. But given that it’s been about 40 years since the last new car with a Quadrajet left the factory and I’ve had no problems getting any parts for them, I don’t expect that to be a problem for many years to come – which might be helpful if “the system” comes unglued. I already have all the parts necessary to rebuild one QJet twice. That should be sufficient for the rest of my life!

At least for the hobbyist/tinkerer, something like Megasquirt might well do the trick at least for cars where the EFI is standalone (not integrated into a web of interlocking computer modules).

(I tried to include a link, but this gets blocked as spam if I do. Just search for it with your preferred search engine.)

The problems with a search term like “Mega Squirts” is there’s enough “pre-verts” out there that have Rule 34’ed it to death.

YES, for the TBI. The “one weird trick” for fixing the elusive problem of fuel loading with a TBI after R&R of the unit or an engine swap is to check the return fuel line for plugging or a kink.

That little problem held me up for weeks after an engine swap was done by a couple of real old school mechanics who usually wouldn’t even attempt anything on a truck with a computer, but they did it for me since I am a customer of many years.

Those guys, who are geniuses on old hotrods, muscle cars, etc. eventually gave up and I took the truck to a guy down the road who found and fixed the kinked return fuel line in an hour. A TBI is, in a few ways, preferable to a carb (for me). I do like the way that the TBI will let the engine start right up no matter how cold it is outside.

Morning, Anon!

I’m a fan of TBI . . . as the next-best thing to a well-tuned carb! I submit for your consideration that my old muscle car always starts – and almost as quickly as car with FI. The Rochester Quadrajet is a magnificent thing – if adjusted corrected. It – and carburetors generally – has a poor rep because many people have no idea how to adjust one. It is analogous to being able to park a car vs. needing “assistance technology” to park it. FI just “works” – until it stops working… and then most people have even less clue how to deal with it. Because the problem is usually something that cannot be seen – i.e., an electronic issue – as opposed to something that can be seen (and physically handled) as with a carburetor. The carb does need more occasional adjustment and sometimes, adjustment “on the road.” But it is adjustable, usually with very basic tools. Carbs also last a lifetime. As in a human lifetime. All of my carbureted machinery – the ’76 TA, the ’75 S1, the ’76 Kz900 – have their original factory installed carbs on them, pushing 50 years after the fact. They will likely still be perched on their intakes after I am gone, too!

What I wonder about is whether mechanical fuel injection, á la the Rochester setup offered on the Corvette and Bonneville or Hilborn stacks, might have been a compromise that delivers the benefits of both carburetors and EFI.

I do know that they were expensive options, and while they were touted as big time power adders, they didn’t add that much power for the money spent (Fun fact: the 1956 Chrysler 300B was the first to break the 1 hp per CID barrier, and the 1957 DeSoto Adventurer had 345 hp out of a 345 CID Hemi as standard in 1957, whereas the Corvette’s injected engine was optional); and in 1957 and 1958, the Tri-Power Bonneville actually had faster 0-60 and 1/4 mile times than the injection version, so they never really took off.

Hi Bryce,

The issue with purely mechanical FI, as I understand these systems, is that they could only be “programmed” for a relative handful of engine speeds/loads, etc. Both EFI and carbs handle the transitions better, are more fluid in their ability to respond precisely to throttle position, engine load and so on.

That makes sense, Eric. That’s probably why not all Chevys and Pontiacs even had it as an option…at least not one that was obvious to the average Joe Schmoe. (In those days, if you had the money and knew the right people, you could get just about any options, even if they weren’t technically available…just ask Chevy’s COPO department or peruse the “Group 19” section of AMC’s parts catalog.)

Plus, when there are far cheaper and easier ways of adding big time power, like boring out engines for more displacement, extra carbs, etc. then mechanical fuel injection is just a lot of hype.

What I liked about carburetors vs. fuel injection on older cars with high-mileage engines: I’d crank the old engine until the oil pressure was up and then tap the accelerator to set the choke, and start – no knocking.

With fuel injection it’s instant starting – hoping there’s a check valve to aid in immediate oil pressure.

Hi libertyx,

Yup; another example of the greater degree of control you had over the vehicle and its systems.

PS: One of the reasons why I revere the Quadrajet is how well it matches EFI without being EFI. Set right, cold starts are almost as immediate and so is throttle response. And the secondaries… well, no EFI system I have ever met can match that!

Hi eric,

Rebuilding a Quadrajet wasn’t too difficult, but to get it “set right” was.

I took my ’80 Camaro Z28 to a fellow who authored a manual on Quadrajets and it took three removals of the carb from the intake, for internal adjustments, and test drives, to get it right. Afterwards, it was perfect but that expertise is getting rare.

My current vehicles are all FI.

Hi libertyx,

Sure, but that’s part of the fun! And: Most of the reported problems with Qjets stem from having to unfix what someone else”fixed.” As they came from the factory, they were usually dead on, with the exception of lean primary jetting in the mid-late ’70s models.

Sometimes – fairly often – someone will maladjust the secondary air door tension or remove the vacuum brake or screw up the float level and any of those will make a mess of things.

Once set up, though, tweaking them is enjoyable – in part because it’s so simple. You just need to be careful about making adjustments, especially the secondary air door tension!

For what it’s worth I’ve found that setting the float at about 1/4 inch is about perfect for a performance set-up. I also adjust the air door tension in very slight increments, about 1/8 of a turn of the screw at a time. I have found it’s best to make that adjustment with the carb off the engine, so you can easily see the “set” hex head screw that has to be – carefully – loosened a little before you – also carefully – turn in or out the tiny screw that controls the spring tension on the doors.

PS: I also once owned an ’80 Z28! Loved the “air induction” hood 🙂

eric,

Re: “air induction” hood scoop

I did some testing, with and without the hood scoop open, and it did make a significant performance improvement when open. So I rigged a switch – scoop was eclectically controlled – installed it on the trans shift lever and could open the scoop at any time, instantly, not just when floored. After a while I just left it always open.

Yup! I did the same with mine. I also did similar with my ’76 TA’s shaker scoop – except it is vacuum powered. It’s pretty cool watching the breathe!

Old had hood scoops. My new has dual air intakes near the grill feeding dense, cool air, and a lot of it.

Nostalgia vs. efficiency – again!

Hi liberty,

Nostalgia, certainly! But also just plain cool. Yes, the “dual air intakes near the grill feeding dense, cool air, and a lot of it” move more air, etc. But the rear-facing flapper door opening in response to the carburetor’s secondaries opening up and engine vacuum pulling the air in is more… cool.

Efficiency – most power/ highest grip/lowest ET – is indeed the thing when we’re racing, especially for money. But something important is lost when you’re not but everything is focused on that end. A greasy sideways-sliding burnout is wasteful of time and rubber; but it’s a hell of a lot more fun than a launch-controlled, no slip, perfectly straight run down the quarter-mile.

Well, it is to me!

eric,

I went from old (’80) to “new” (2012) as the last chance to enjoy the meaningful engineering advances without the excesses of today (post 2012).

Hi libertyx,

I would have kept the ’80, though. Last of the no-ECU Interceptors! (In ’81, as you probably know, the Camaro got an electronic Quadrajet). Small block Chevy V8, about as simple as it gets and yet also very everyday (or at least, as often as you need to) drivable. But I take your point. I dig my ’02 Nissan for the same reasons as you dig your 2012. I figure mine has at least another ten years and 150k to go before anything major becomes an issue. The question becomes what to do then…

Another much maligned carburetor was the Carter ThermoQuad found on Mopars. They got a bad rep for stumbling and poor driveability when cold. The real culprit was the heat riser, which on the B-block engines like the 400 and 440 of the same vintage as the TQ, wasn’t easily to get to, even on a big Mopar like a New Yorker or Royal Monaco. You HAD to apply heat riser solvent and work that flapper valve at EVERY oil change, or the damn thing would readily seize up. Everything was predicated on that heat riser diverting hot exhaust gas right away to warm up the intake manifold; in order to meet emissions and get some decent (for those big beast, 12-13 mpg around town WAS ‘decent’) fuel economy, they pulled off the choke right away and open, and were set lean.

Hi Doug,

Yup! I had a friend with a 440 that had one of those. As you say, the main issue wasn’t the carb, per se, but rather the gimps fitted to them to make them “compliant.” As a related aside, the QJet I just finished going through had those vile idle limiter caps and – once you got the caps off – you need a special micro-small tool to make fine adjustments. With the older models, a common flat-blade screwdriver was all it took.

Living in a state where the elevation varies from 4,500 feet to 14,000 feet (sometimes in an hour) and we can all four seasons in a day, I don’t share the completely negative view of fuel injection. But suffice to say for the oiling aspect you can easily mimic this feature with a switch or simply removing a fuse. Then crank to your heart’s desire. Not to mention, putting a hidden switch in a fuel pump or ECU circuit can be a very effective theft preventative as well.

As far as repairability, I dunno, I had the same injectors on my 1991 Toyota from the day it was built until the day I sold it in December 2015 with one renewal of their seals in 2006 when I pulled them in an engine refresh. I built a little circuit to ping the coils with a periodic pulse while letting them sit in a cheap ultrasonic jewelry cleaner for a couple of days. Sum total of about $20 in seals, $15 Walmart cleaner and an Arduino controller, power supply and a few FETs from the junk box. I guess I can’t really find much fault in 300,000 miles and 25 years from 4 little electronic fuel nozzles.

I’m no spring chicken, solidly Gen X straddling Baby Boomer “duct tape and bailing wire” and the Millennial’s “just write some code” version of the DIY ethos. We get a misremembered version of the good old days sometimes. Gotta remember all the poorly designed and built crap has long since gone to the big junkyard in the sky so we have a skewed version of history since we only see the stuff worthy of surviving.

When I was a teenager I remember everyone being scared of the new cars with fuel injection. Back then I cleaned and rebuilt my share of carburetors. Since then All the fuel injected vehicles I’ve owned have been very reliable. My only repairs have been oxygen sensors. I really don’t miss carburetors.

Hi Bin,

Indeed, EFI (and TBI more so) is very reliable. Until it’s not. These systems work like the proverbial Swiss watch for 15 years or so. But – like anything electronic – they do not last forever. And when those electronic components – plural! – begin to fail, they have to be replaced.

The problem then is that cost of those parts – and the usual paying someone to replace them – is often prohibitive relative to the value of the car at that point.

The carbureted system is inherently longer-lived because of its rebuildability and low cost. As I mentioned in the article, the carb I am rebuilding constitutes the entirety of the fuel delivery system of the car it was installed on originally, a 1978 Trans-Am. I’ve rebuilt it to operationally as-new condition for – here it comes! – about $50 in small parts plus my labor. This is about the cost of a single O2 sensor or injector for an EFI system.

Granted,not everyone wants to fiddle with a carb – obviously. And many people are fine with a vehicle that runs practically maintenance-free for 10-15 years, which is understandable. But baked into this is a need to replace the vehicle more often, which means spending a great deal more money – and for most people, more debt. Which means being tied into the “system,” which seems to me to be a not-so-good idea at this moment in time!

The lack of longevity is a cost not often noted in the general description of modern cars. They do indeed run far more trouble free for their shorter lifespan. A “tuneup” now consists mostly of changing spark plugs and wires, and may not need doing but a few times in the life of the car. Instead of every 20k miles or so. Likewise the environmental costs of the same are ignored as much as possible, if not entirely. There is a lot of energy consumption in making a car, and delivering it, and a lot of material, much of which involves mining. Funny how California takes no note of these costs when mandating the replacement of old tech, or simply outlaws a semi tractor because of its age, which they did several years ago

Eric,

My dad was known as the “carburetor kid” in his youth. Today he considers the throttle-body a good compromise. I love the DIY aspect of the classic cars that is nearly completely missing from those modern, though I didn’t so much care for the difficulties of starting carb-equipped cars.

As far as replacing electronic parts, I don’t know if you ever read my message about the MAP sensors in my 1994 S10. I have gone through EIGHT now, either exchanged or purchased. I’ve built two to try and fix the issue. The latest one I built the other day, using a 5V pressure sensor, has the truck running like a bat-outta-Hell, but it still failed the go&%$mned emissions test! Runs a little too rich still, generating slightly too much CO and passing a bit much unburned fuel for the Federal Govt’s arbitrary requirements. Pisses me right off!

You ever hear of anyone else going through 8 non-functional “new” parts? Most people don’t even believe me, but I can prove it!

Hi BaDnOn,

Miserable – in re the garbage MAP sensors. And – yes – I get this a lot because my buddy Tim, the mechanic, gets it a lot. Brand-new parts that don’t work or don’t work well. And this is why I much prefer mechanical stuff. It can almost alway be fixed because you can make/correct a mechanical part so that it works. Electronic parts come out o’ the box as things that work or not and if not, you generally lose.

Right now, I am mourning the two complete Pontiac V8s I sold for next to nothing to get them out of my way. One was a RA III 400 (with the 48 heads) ands the other a 2 bolt 455 from a Catalina. The crank in that one is worth $1,000 now.

Errrrrrrrrr!

Damn, those look like nice cars. Be careful!

Also, would you do an angry, scathing article decrying emissions testing? Just another guilty-until-proven-innocent nightmare brought to you by urban sadists.

This is an excellent point. I have bee trying to veer more towards systems and things that don’t require massive centralized manufacturing facilities and systems. Like not if, but WHEN many of these systems collapse. The further divorced you are from them the better off you’ll be.

Physical copies of books, hand tools, (as opposed to power tools), backup generator with 500 extra gallons of propane (which has an indefinite shelf life as opposed to gas and diesel). Currently all our vehicles except the bicycles are EFI.

Dammit Eric!

Now I have another project to pursue?…

May have to look at that 70’s era CJ jeep for sale down the road now.

Good ideas. Failing to prepare is preparing to fail. This card-house has been in the wind longer than is reasonable.

Definitely time to collect old carburetors when you can find them, keep them. Sediment bulbs too, keep them.

Don’t have a truckload of them, but I find them here and there on the farm discarded but not thrown away.

Catalytic converters too, all are worth 70-90 dollars, truck catalytic converters worth even more. Got a junkyard full of old junked/wrecked cars, not a bad way to get some money.

Wear your facemask all of the time, might as well be a crazy fool like Howie.

One of my daughters lives in Colorado. On a visit to see her, her roommate was wearing a mask all of the time, never fail. It was 2018 in October. Her roommate is a nurse, sure was strange to see someone always wearing a mask, never saw her face. I dunno, couldn’t figure out why someone would wear a mask all of the time. Just is not normal.

The road of excess leads to the palace of wisdom – William Blake

Eventually, the excess mask wearing will lead to being wise enough to finally realize they don’t do squat, are feckless.

It’s National Beer Drinking Day, which is everyday.

“… the computer that runs it all. Which you can’t rebuild for $75 on your bench after a little scrubbing with a toothbrush and some solvent.”

Such as the infamous Body Control Module, an expensive, proprietary and (usually) unrepairable electronic device.

Imagine open-source coding on all IC-engined vehicles, with the digital processing handled by a $50 off-the-shelf Raspberry Pi computer-on-a-board. No more $1,200 repair bills for replacing a BCM; lots of opportunity for creative young coders to add functionality and upgrade the user interface.

Tragically, by making digital vehicle components opaque, proprietary, unrepairable and un-interchangeable, the legacy auto industry is killing off the IC engine.

Hotrodding has transitioned to retrofitting classic vehicles with electric drive trains, because they’re so much more modular and adaptable.

Saving the IC engine is going to require a total rethink by new participants in place of the legacy auto companies, who have learned to love Big Brother’s regulatory moat that protects them from new entrants with dangerous ideas about actually serving the customers.

Meanwhile — speaking of ‘opaque and proprietary’ — Boeing’s crash-by-wire 737MAX has won approval from Europe to ‘fly and die’ again. 🙁

This is my first thought too. Carburetors are strictly a form-follows-function device. ECMs should be the same, and they were for a time. Hardware is pretty generic stuff, microcontrollers, solenoids, potentiometers, wire. Raspberry Pis are way overkill, a simple ARM Cortex 0 running Arduino or other RTOS would be plenty. Reverse engineering consists of popping the EPROM chip into a reader and running a reverse compiler. But Uncle started putting the responsibility for pollution on the manufacturer, not the owner. Soon everything became opaque and proprietary because if the ECM code was modded it wouldn’t pass testing, even if it were made more efficient and therefore emitted less “pollution.”

If we follow this to the logical end, the next generation of automobiles won’t just have a display that makes a sad face when you mash the gas pedal and smiley face when you drive like an old lady, it will have governors that prevent 0-60 times from going above whatever is deemed necessary to get the fuel economy where Uncle decides it should be. And any modification to restore performance will be verboten.

An RPi does not (IMHO) have the I/O speed and fan-out to handle an EFI application. There are non-proprietary solutions out there though (Megasquirt for one) that do, and they’re not expensive.

There is one EFI system that is end-user-repairable (well, if you have a grasp of electronics that is), I have one sitting in the garage now (if I can ever get time and $$$ to fix the dropped valve seat)…the VW Types 3 and 4 came with Bosch D-Jetronic starting in around 1970, along with Volvos, Jags, and Bentzes. D-Jet is analog electronic, the “computer” is all discrete components, and can be repaired both mechanically and electronically with parts still available, as long as the MPS is still OK. Even that can be patched up for the most part. Works pretty well, though it is “tuned” for the application by circuit changes vice software constant tweaks. Absolutely no cold start, idling, etc. issues with D-Jet, as long as the MPS is OK. If it’s not, Katy bar the door on mixture control!

Bosch K-Jet was really 100% mechanical fuel injection, and usually pretty reliable, though not easily tuneable.

I shall not utter the names Kugelfischer (BMW 2002tii) or Spica (Alfa) here 🙂

For EFI, I’m thinking of something like Megasquirt with a back-up ECU, if I ever get back to the 412 in the garage, since there is no room in the engine bay for other than the Euro-version dual carbs, and they are extremely scarce in the US. Otherwise, for carbies in general, the simplest and easiest to repair I’ve ever messed with on a car has to be the hoary old SU HS series. Bloody brilliant design. I think Keihin or maybe Mikuni cribbed it for motos, I know Hitachi did for certain Japanese cars, like the Datsun 240Z.

Don’t tell people actually doing engine control with RPi boards that it can’t be done.

https://arxiv.org/abs/1310.3567

That article was 5 years ago and not doing simple control it was real time learning with an 26 GPIO ARM11 Raspberry Pi 1.

Now, geez, the RPi 4 is 64-bit Cortex running 1.5 GHz (this alone has roughly 30 times the raw performance a RPi 1), Gigabit Ethernet, 40 GPIO, 8 GB DDR4 machine.

You don’t even need to be an elegant machine coder anymore. You do, like always, need to build real world I/O capable of handling the sensors and loads.

Here’s an article on what Adam Vaughan (now I understand Dr. Vaughan, PhD) did in a less academic discussion.

https://hackaday.com/2015/01/28/raspberry-pi-learns-how-to-control-a-combustion-engine/

I still prefer the SU mechanical computer for fuel control (carburation that is), just wish they were cheaper new nowadays.

OK then, someone has worked out how to get the fine pulse timings required for EFI on the I/O right with an RPi. I stand corrected.